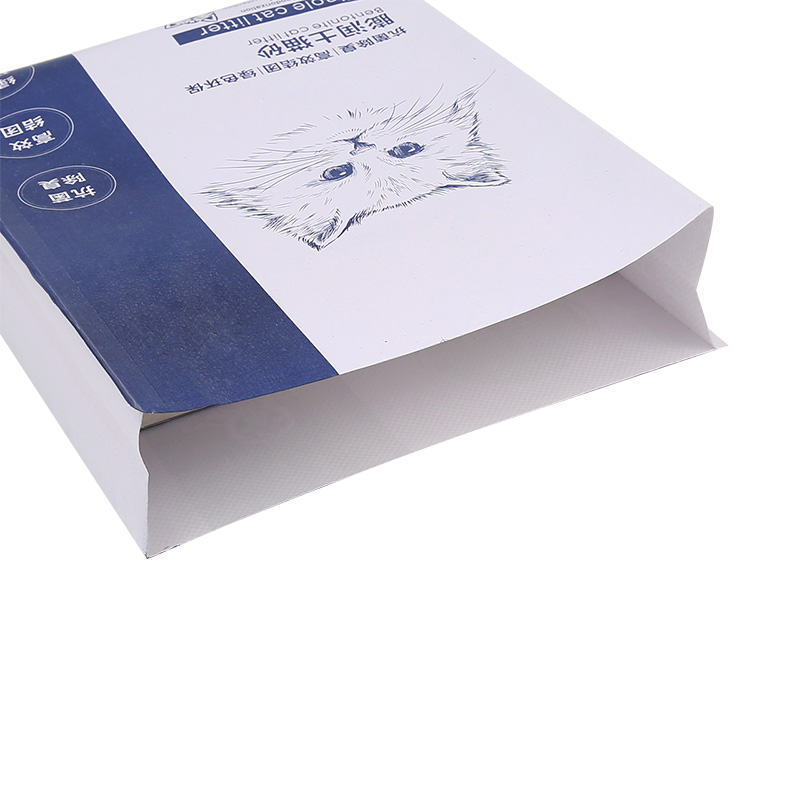

The Color Printing Open M-Edge Bottom Stitching Woven Bag is a versatile and durable packaging solution widely used across various industries. Designed with precision and strength, this bag offers good performance for products requiring robust and efficient containment.

Durability and Structural Integrity

Engineered with high-quality polypropylene fabric, the woven bag is built to withstand heavy-duty use. The open M-edge bottom stitching enhances the bag's structural strength, reducing the risk of tearing or leakage even under pressure. This makes it ideal for packaging materials like cement, titanium dioxide (TiO₂), and chemical powders. The M-edge stitching also helps the bag maintain its shape during transportation and stacking, which ensures a stable and organized shipping process.

Advanced Color Printing for Brand Visibility

With High-quality color printing capabilities, the woven bag supports detailed and vibrant graphics, ideal for showcasing branding, handling instructions, and product information. This feature adds professional appeal to retail packaging such as pet feed bags, food packaging, and cosmetic powders. Whether used for carbon black bags or latex powder bags, the printing remains clear and wear-resistant over time.

Wide Range of Applications

The Color Printing Open M-Edge Bottom Stitching Woven Bag is suitable for a broad spectrum of applications. It is commonly used for:

Building material powder bags

Cement bags

Titanium dioxide bags

Latex powder bags

Chemical valve bags

Carbon black bags

Pigment powder packaging bags

Starch packaging

Food packaging

Fertilizer packaging bags

Pet feed bags

Each application benefits from the bag's reliable construction and ease of use. For instance, fertilizer packaging requires both moisture resistance and robust handling, which this woven bag offers. Similarly, chemical valve bags need secure closure and sturdy build—features well addressed by the M-edge design.

Ease of Use and Customization

These woven bags are available in a range of sizes and can be customized to suit specific product weights and volumes. The open-top design makes filling quick and efficient, while the stitched bottom ensures secure sealing. Businesses packaging pigment powders, starch, or construction powders can choose specifications that match their operational requirements.

Eco-Friendly and Cost-Efficient

As sustainability becomes more important, the Color Printing Open M-Edge Bottom Stitching Woven Bag provides a reusable and recyclable alternative to traditional packaging. Its long-lasting nature also reduces replacement frequency, offering better cost-efficiency over time. From titanium dioxide bags to pet feed bags, this solution balances environmental concerns with high functionality.

With its strong materials, clean design, and reliable performance, the Color Printing Open M-Edge Bottom Stitching Woven Bag continues to be a trusted choice for industries ranging from construction to agriculture. Whether you're packaging cement, food, or chemical powders, this woven bag is engineered to meet your packaging demands with reliability and professionalism.

English

English Español

Español عربى

عربى