The Oblique Paper Plastic Valve Bag is a highly functional packaging solution designed to meet the demands of various powder and granular materials. This bag structure combines the strength of plastic with the breathability and printability of paper, providing a reliable and efficient method of storing and transporting a wide range of materials. With its oblique valve design, the bag allows for easy and clean filling while Small product leakage, making it an good choice for automated packaging lines.

Key Features and Advantages

One of the main advantages of the Oblique Paper Plastic Valve Bag is its hybrid composition. The outer paper layer provides rigidity, good stackability, and good surface printing for branding, while the inner plastic liner offers moisture resistance and durability. This combination ensures long-lasting protection, especially for sensitive or high-value materials.

The oblique valve opening is designed for high-speed filling and self-closing capabilities. This design not only increases filling efficiency but also helps reduce dust generation during packaging. It is compatible with great majority valve bag filling machines, making it ideal for high-volume production environments.

Applications Across Industries

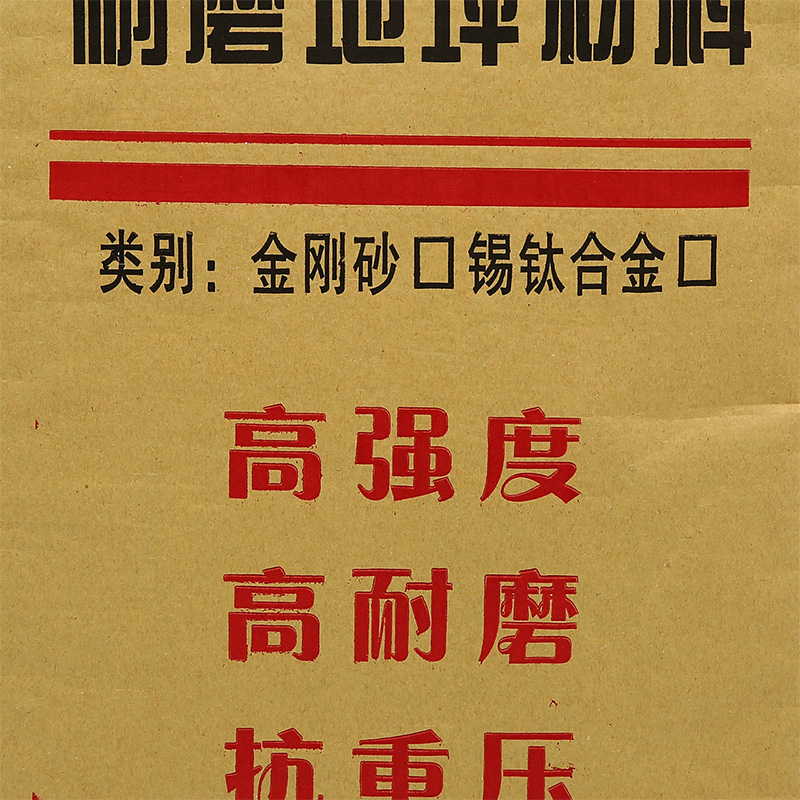

The Oblique Paper Plastic Valve Bag is widely used in various industries. For building materials, it serves as a reliable cement bag, offering strength and moisture protection. In the field of titanium dioxide packaging, the bag ensures the product remains uncontaminated and secure during transport. For latex powder and pigment powder packaging, its sealing and anti-leak design are particularly beneficial.

The bag is also suited for the chemical industry, used as a chemical valve bag for a variety of powders and granules. Its durability is a key asset when transporting carbon black, which requires a dust-tight and robust package. As a starch packaging solution, the bag keeps the contents dry and safe from environmental exposure.

In the food industry, the Oblique Paper Plastic Valve Bag plays a significant role in maintaining hygiene and extending shelf life for various products. It is an good choice for fertilizer packaging, resisting punctures and tears during handling and distribution. Additionally, for pet feed packaging, the bag offers secure sealing and convenient handling, making it easier for retailers and consumers alike.

Sustainability and Efficiency

Another strength of the Oblique Paper Plastic Valve Bag is its potential for recyclability. Many variants can be produced using environmentally friendly materials, aligning with modern sustainability standards. The design also Small product waste and improves shelf efficiency due to its shape-retaining form and stackability.

Its performance in automated filling systems reduces labor costs and enhances productivity. This efficiency makes it a First choice packaging choice for companies handling cement, titanium dioxide, latex powder, chemical powders, carbon black, pigments, starch, fertilizers, food powders, and pet feed.

The Oblique Paper Plastic Valve Bag stands out as a versatile and efficient solution for industrial packaging needs. Whether used as a cement bag, chemical valve bag, titanium dioxide bag, or for pet food and fertilizer packaging, it offers consistent protection, ease of use, and a professional presentation. With its multi-industry compatibility and reliable performance, this packaging format continues to gain preference among manufacturers worldwide.

English

English Español

Español عربى

عربى