The agricultural sector requires efficient, durable, and cost-effective packaging solutions to ensure that products reach their destination safely. Among the available options, PP woven bags have become increasingly utilized for the distribution of agricultural products due to their strength, flexibility, and adaptability. These bags are suitable for transporting a variety of items, ranging from grains and seeds to animal feed, offering protection against physical damage and environmental factors such as moisture and dust.

One significant advantage of PP woven bags is their versatility. They can be manufactured in different sizes and designs depending on the specific needs of agricultural producers and distributors. For example, smaller bags may be used for retail distribution of grains or pulses, while larger bags can handle bulk shipments of commodities like rice, wheat, or corn. Their woven structure provides tensile strength, allowing the bags to hold substantial weight without tearing, making them practical for both manual handling and mechanical transportation.

In addition to agriculture, PP woven bag cement is a widely used option in the construction industry. These bags are specifically designed to carry heavy materials such as cement while maintaining stability during transport. Their robust construction ensures that cement is delivered safely to construction sites, preventing product loss and less dust release. The ability of PP woven bags to endure rough handling makes them suitable for various stages of the supply chain, from production facilities to final delivery.

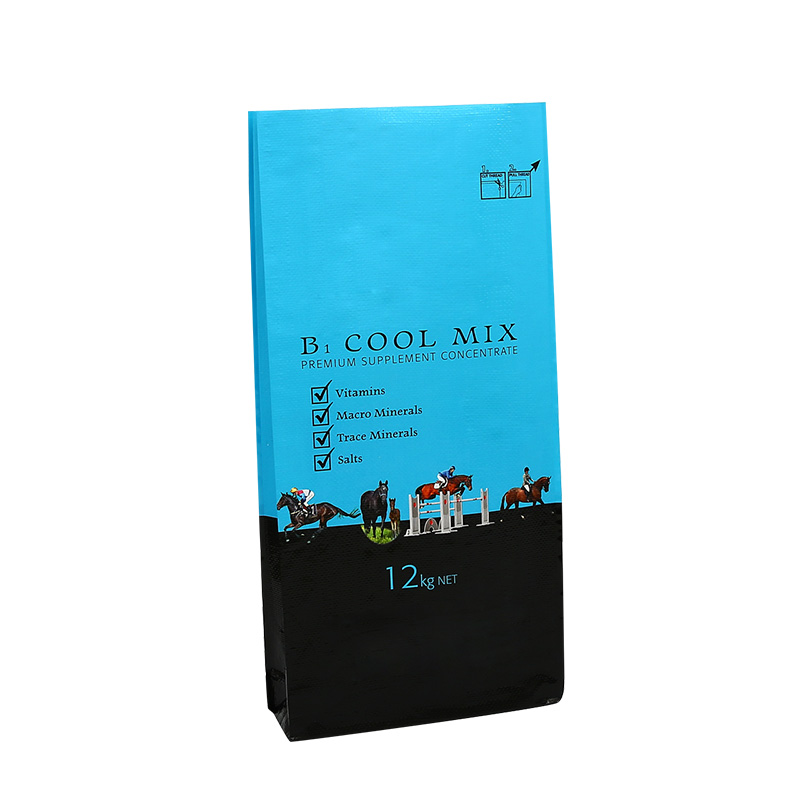

Another variation in the packaging sector is the kraft block bottom bags, which are often applied to both agricultural products and industrial goods. These bags feature a strong kraft paper inner layer combined with a woven outer layer, creating a protective and stable package. The block bottom design allows the bag to stand upright independently, facilitating storage, filling, and transportation. This design is particularly advantageous for bulk grains, seeds, or powdered agricultural products, as it reduces spillage and simplifies stacking during shipment.

The use of PP woven bags and kraft block bottom bags in agricultural distribution aligns with growing demands for sustainable packaging. Many manufacturers focus on producing bags that can be reused or recycled, reducing the environmental impact associated with single-use plastics. These bags are often lighter than traditional alternatives, which helps reduce transportation costs and the carbon footprint of supply chains. Moreover, the durability of PP woven bags ensures that fewer replacements are required, contributing to resource efficiency across the agricultural distribution process.

Proper labeling and design customization are other notable aspects of PP woven bag cement and agricultural packaging solutions. Bags can be printed with product information, handling instructions, or branding details, allowing distributors to communicate important information clearly. Customized designs also improve operational efficiency, as workers can quickly identify the contents of each bag and manage storage or loading accordingly. For agricultural products, labels may include details such as origin, grade, or expiration dates, supporting compliance with regulations and standards in different markets.

The versatility of these bags is further demonstrated by their adaptability to various filling and sealing methods. Whether filled manually or using automated equipment, PP woven bags and kraft block bottom bags are compatible with modern packaging systems. Sealing methods such as stitching or heat sealing ensure that the contents remain secure during transport, resulting in less product loss and maintaining quality. These packaging solutions provide a balance between strength and flexibility, which is essential for managing agricultural goods efficiently.

In addition to their functional benefits, PP woven bags offer cost-effectiveness for agricultural producers. The materials used in production are widely available and economically feasible, making these bags a practical choice for high-volume distribution. Their durability reduces the risk of damage, lowering replacement costs and potential losses during transportation. Furthermore, their stackable design and stable structure improve warehouse efficiency, allowing distributors to optimize storage space and manage inventory effectively.

Overall, the application of PP woven bags, PP woven bag cement, and kraft block bottom bags in agricultural product distribution provides a reliable, adaptable, and sustainable packaging solution. These bags support the safe handling, transport, and storage of a wide variety of agricultural commodities while meeting the operational and environmental needs of modern supply chains. By offering strength, versatility, and practicality, these packaging options continue to play a significant role in ensuring that agricultural products reach their intended destinations efficiently and securely.

English

English Español

Español عربى

عربى