Handling bulk powders in industrial, food, and chemical applications presents unique challenges. Efficient storage, transportation, and discharge require packaging solutions that protect the material while facilitating easy handling. Valve bags have become a key solution for many industries, offering reliable performance and improved handling characteristics compared to traditional packaging.

Valve bags are specifically designed to simplify the filling and emptying process. Unlike standard open-mouth sacks, a valve sack features a built-in self-closing valve that allows automatic filling with small dust emission. This design reduces material loss, protects the surrounding environment, and lessens operator exposure to potentially hazardous powders. Whether the product is cement, flour, or powdered chemicals, valve bags contribute to cleaner and more efficient bulk powder handling.

One important aspect of modern valve bag production is the use of plastic paper packaging. Combining layers of paper and plastic creates a composite material that provides both strength and moisture resistance. Paper gives the bag structural integrity, while plastic adds a barrier against moisture, preventing clumping or contamination of the powder. This combination allows valve bags to perform well under heavy loads during storage and transportation, maintaining the quality and flowability of bulk powders.

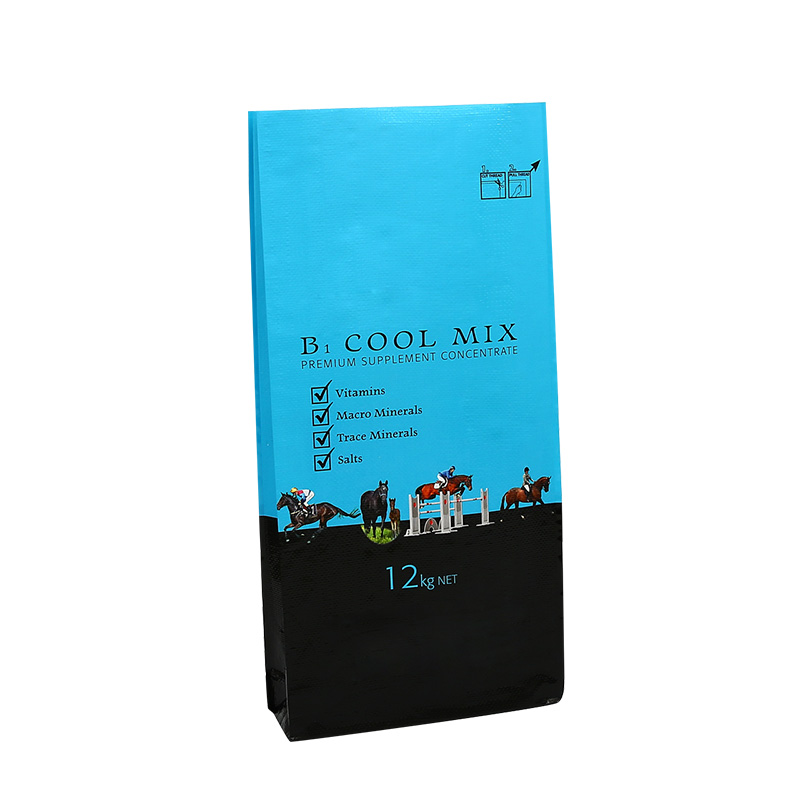

In addition to material construction, PP woven bag printing plays a crucial role in industrial applications. PP woven bags, often used as an alternative to paper-based valve sacks, provide durability and resistance to tearing. Printing on these bags not only serves branding purposes but also ensures compliance with labeling regulations and safety standards. Clear printed information, such as product type, handling instructions, and batch numbers, supports proper logistics and inventory management. For industries where traceability is critical, high-quality printing on PP woven bags helps maintain transparency throughout the supply chain.

Valve bags also enhance handling efficiency by allowing precise filling and stacking. Their uniform size and robust construction make them compatible with automated packing lines and palletization systems. Forklifts and conveyor systems can move filled bags more safely and efficiently, reducing manual labor and potential workplace injuries. In large-scale operations, even small improvements in handling efficiency can translate into significant cost savings and productivity gains.

Another advantage of valve sacks is their adaptability to different bulk powders. With various material compositions, valve bags can accommodate products ranging from fine powders to granulated chemicals. By selecting the appropriate combination of paper, plastic, or PP woven layers, manufacturers can tailor the bag properties to the product requirements. This flexibility allows industries to optimize storage conditions, prevent contamination, and lessen environmental impact.

Environmental considerations are increasingly important in packaging selection. The use of recyclable materials in valve bags, including certain plastic paper packaging and PP woven options, supports sustainability initiatives. Recycling programs for industrial packaging help reduce waste and contribute to a circular economy. Moreover, valve bags' efficient design reduces product loss during filling and discharge, further lowering environmental impact.

Safety is another critical factor. Valve bags reduce dust generation, a common concern when handling bulk powders. Dust can cause respiratory hazards for workers, affect product quality, and increase cleaning and maintenance needs in facilities. By containing the powder within a secure bag design, valve sacks lessen these risks, creating safer working environments and more reliable storage solutions.

Valve bags provide a practical and effective solution for bulk powder handling. Their design supports easy filling, controlled discharge, and secure storage. When combined with plastic paper packaging or high-quality PP woven bag printing, valve sacks deliver enhanced durability, moisture protection, and traceability. Across industries, these bags help maintain product integrity, improve operational efficiency, and contribute to safer, cleaner, and more sustainable handling of bulk powders. For companies looking to optimize their packaging strategy, valve bags offer a versatile option that meets both practical and regulatory needs.

English

English Español

Español عربى

عربى