Technological advancements in polypropylene (PP) woven bag production are redefining packaging standards. Improved weaving techniques, enhanced coatings, and better sealing options have expanded their performance range, making them suitable for both heavy-duty and sensitive applications. Variants like white PP woven bags, PP gunny bags, and jumbo industrial bags illustrate how innovation continues to drive adoption in diverse industries.

One of the notable developments in the production of PP woven bags is the refinement of raw material selection. Manufacturers are now able to use higher-quality polypropylene fibers that offer improved tensile strength and resistance to wear and tear. These fibers ensure that white PP woven bags maintain a clean appearance while providing reliable protection for packaged goods. The use of advanced weaving techniques has also contributed to more uniform fabric structures, reducing weak points that could advance to tearing during handling and transportation.

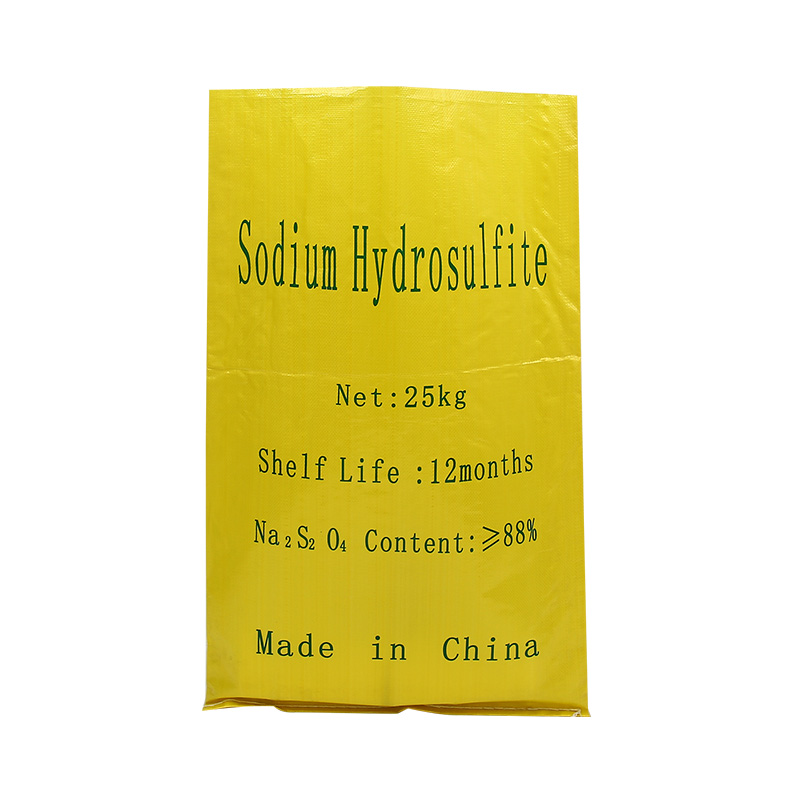

In addition to raw material improvements, printing and coating technologies have progressed considerably. Modern PP woven bags can now accommodate high-resolution printing, which allows for clear branding, labeling, and product information. Coatings applied to the bag surface improve moisture resistance and reduce dust penetration, which is particularly important for applications involving food or sensitive industrial materials. For PP gunny bags, these coatings can enhance durability while retaining the traditional woven texture preferred in certain agricultural and bulk handling contexts.

Automation has played a critical role in increasing production efficiency and consistency. Machinery allows for precise control over bag dimensions, weaving density, and stitching patterns. This is especially relevant for industrial jumbo bag production, where uniformity is essential to ensure safe handling of large-volume materials. Automated inspection systems also detect defects early in the production process, reducing material waste and ensuring that each bag meets required specifications.

Sustainability has become an important consideration in PP woven bag manufacturing. Advances in recycling technology allow for the reuse of polypropylene material without significantly compromising bag performance. Manufacturers can now produce white PP woven bags and other types using recycled content, reducing the environmental footprint of packaging operations. Additionally, innovations in energy-efficient machinery have decreased power consumption and carbon emissions, contributing to more environmentally responsible production.

Functional enhancements in bag design are another area of technological progress. Modern PP gunny bags are designed with reinforced stitching and adaptable gussets, improving load-bearing capacity and ease of handling. For industrial jumbo bag production, the integration of features such as looped lifting straps and secure closure systems ensures safe and efficient transport of bulk materials. These design improvements not only enhance operational safety but also contribute to reduced labor costs and handling time.

The versatility of PP woven bags has expanded due to these technological advances. White PP woven bags are increasingly used in food-grade applications, while PP gunny bags remain popular for agricultural products such as grains, seeds, and fertilizers. Industrial jumbo bags are widely employed in sectors such as construction, chemicals, and mining, where they provide a reliable solution for transporting large quantities of material. The adaptability of PP woven bags ensures they can meet diverse storage and transportation requirements across industries.

Technological developments in PP woven bag production have led to significant improvements in material quality, manufacturing efficiency, sustainability, and functional design. White PP woven bags, PP gunny bags, and industrial jumbo bags now offer enhanced durability, moisture resistance, and versatility, making them suitable for a wide range of industrial and commercial applications. As production techniques continue to evolve, PP woven bags are expected to remain a vital packaging solution that balances performance, cost, and environmental considerations.

English

English Español

Español عربى

عربى