Businesses across different sectors are seeking packaging options that provide strength, efficiency, and reduced environmental impact. Among the many solutions available, PP woven sacks have emerged as a reliable choice for diverse industries such as agriculture, food, construction, and chemicals. Their combination of durability and sustainability makes them an important material in the transition toward eco packaging solutions.

Strength and Versatility of PP Woven Sacks

PP woven sacks are made from polypropylene strips that are woven together to form a strong, flexible material. This process gives the bags high tensile strength while keeping them lightweight, making them well-suited for bulk packaging. Industries that deal with products such as grains, seeds, fertilizers, powders, and building materials frequently rely on this type of sack for safe storage and transport. The weaving process allows for ventilation where required, while laminated versions can provide moisture protection. This adaptability supports a wide range of applications.

PP Woven Valve Bag Applications

One of the practical designs within this category is the PP woven valve bag. These bags include a valve mechanism that enables efficient filling of powdered or granular products. Once the bag is filled, the valve automatically closes under product pressure, offering a secure seal without the need for additional stitching or heat sealing. This design makes handling quicker in industries such as cement, chemicals, and food powders, where efficiency in packaging operations is crucial. The valve system also reduces product leakage and waste, aligning with the principles of sustainable packaging.

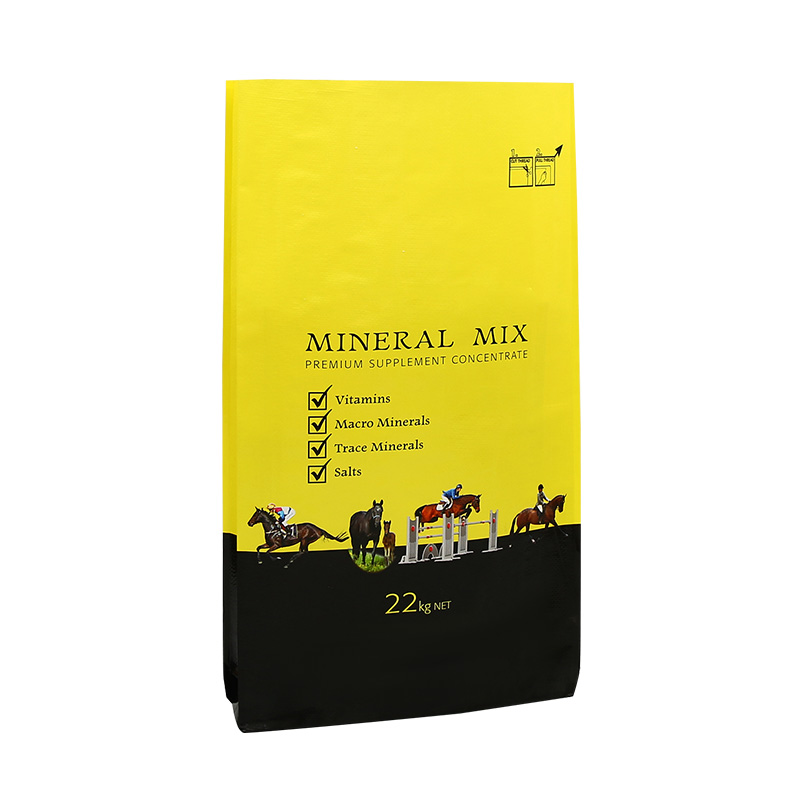

Sealed Product Packaging for Food and Chemicals

Another growing application of PP woven sacks lies in sealed product packaging. While traditional woven sacks are known for strength, advancements in coating and lamination have enabled them to be adapted for airtight packaging requirements. For example, when storing rice, flour, sugar, or chemical powders, the ability to maintain freshness and prevent contamination is vital. Sealed PP woven sacks provide both strength and barrier properties, protecting contents from moisture, dust, and pests. This ensures that the quality of goods is preserved throughout transport and storage, reducing spoilage and contributing to more sustainable supply chains.

Contribution to Eco Packaging Solutions

One of the key drivers behind the increasing use of PP woven sacks is their role in eco packaging solutions. Unlike single-use plastics that are discarded after one use, PP woven sacks are durable and reusable multiple times. Their strength allows them to be repurposed, and after their life cycle, they can be recycled into other polypropylene products. This contributes to reducing packaging waste and supports circular economy initiatives. Furthermore, compared with some traditional packaging materials, PP woven sacks can reduce the overall volume of packaging waste, making them a more sustainable choice for industries looking to improve their environmental footprint.

Economic and Logistical Benefits

Beyond sustainability, PP woven sacks also offer practical advantages in logistics and transportation. Their lightweight structure helps lower shipping costs, while their high load-bearing capacity ensures safe handling of bulk materials. The ability to customize sack sizes, printing, and lamination options allows companies to align packaging with specific supply chain requirements. Reusability reduces the need for frequent replacement, saving resources and lowering costs in the long run. When combined with features such as valve mechanisms or sealed packaging, these sacks present a highly adaptable solution for modern packaging demands.

Future Outlook for PP Woven Sacks

As industries continue to place emphasis on sustainability and resource efficiency, the applications of PP woven sacks are expected to expand further. New technologies in lamination, digital printing, and biodegradable coatings are likely to enhance their functionality. Future developments may focus on improving recyclability and increasing the proportion of recycled polypropylene used in production. These improvements will allow PP woven sacks to remain relevant in sectors ranging from construction and agriculture to food and chemicals, where strong yet environmentally considerate packaging is increasingly valued.

The evolution of PP woven sacks demonstrates how packaging can balance strength, practicality, and sustainability. From the efficient design of the PP woven valve bag to the protective qualities of sealed product packaging, these sacks are contributing to safer storage, reduced waste, and more eco-friendly supply chains. Their role in eco packaging solutions ensures that they will remain a vital choice for industries seeking to meet both operational needs and environmental goals.

English

English Español

Español عربى

عربى