Growing environmental awareness and rising ethical expectations have placed social responsibility at the forefront of the packaging manufacturing industry. Instead of focusing solely on cost and operational efficiency, manufacturers are now expected to consider the broader impact of their products and processes. This shift is driving changes in material selection, production methods, and supply chain management as companies work to align with sustainable development goals and meet the expectations of customers, regulators, and business partners.

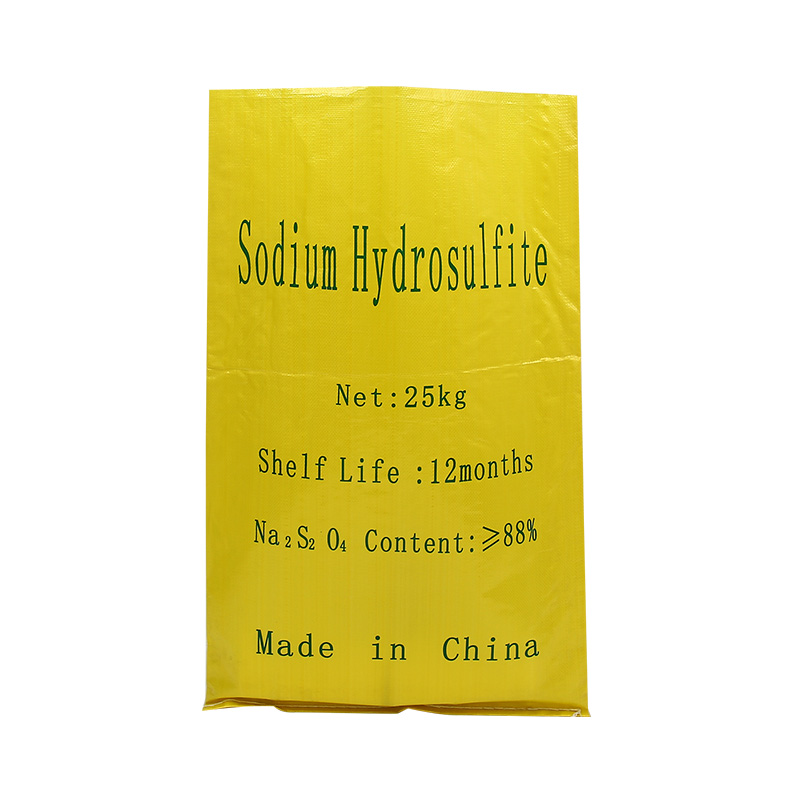

One area where social responsibility is evident is in the development of HDPE woven bags. These bags, made from high-density polyethylene, offer durability and versatility for various industrial and commercial applications. Manufacturers of HDPE woven bags are exploring ways to reduce environmental footprints by using recycled materials and implementing energy-efficient production methods. Beyond sustainability, these bags contribute to safer handling of bulk products such as chemicals, grains, and construction materials, reducing risks during transportation and storage. By considering both environmental and human safety factors, producers demonstrate a broader commitment to social responsibility.

Similarly, the rise of eco packaging bags reflects the industry's shift toward environmentally conscious solutions. Eco packaging bags are designed to reduce waste and support recycling or composting where possible. Their adoption spans multiple sectors, including retail, agriculture, and logistics. Manufacturers are increasingly investing in materials that can decompose naturally or be reused without significant degradation in quality. Using such eco packaging solutions allows companies to meet regulatory requirements while responding to growing consumer demand for sustainable practices. It also encourages responsible disposal habits and contributes to the circular economy, where resources are continuously cycled back into production rather than discarded.

The evolution of flexible food packaging bags also highlights social responsibility in the manufacturing process. These bags are designed to protect perishable goods, extend shelf life, and reduce food waste. In addition to using safe, food-grade materials, manufacturers often focus on lightweight, efficient designs that lower transportation emissions. Flexible food packaging bags can be tailored for specific products while maintaining compliance with health and safety standards. By prioritizing material safety and functionality, producers of these bags not only protect consumers but also reduce environmental impact throughout the product's lifecycle.

Social responsibility in packaging manufacturing extends beyond materials. It encompasses workforce practices, supply chain ethics, and community engagement. Companies are adopting transparent sourcing policies to ensure that raw materials for HDPE woven bags, eco packaging bags, and flexible food packaging bags are obtained responsibly. Labor standards, fair wages, and safe working conditions are being emphasized to support the well-being of employees. This approach strengthens both internal and external trust, positioning the company as a responsible actor in the global market.

Moreover, innovations in production techniques demonstrate how social responsibility can intersect with technological development. Energy-efficient machinery, waste reduction programs, and water-saving initiatives are becoming standard in facilities producing HDPE woven bags, eco packaging bags, and flexible food packaging bags. These measures not only reduce costs but also mitigate the environmental footprint of manufacturing. They reflect a broader understanding that responsible operations are integral to long-term business sustainability.

Consumer education is another critical aspect of social responsibility. Packaging manufacturers are providing clear instructions on recycling or reusing products, especially in the case of HDPE woven bags and eco packaging bags. Informing end-users about proper disposal methods ensures that sustainable materials achieve their intended environmental benefits. Similarly, promoting awareness about the advantages of flexible food packaging bags in preserving food quality and reducing waste encourages more responsible consumption habits.

Social responsibility in packaging manufacturing involves a holistic approach that integrates environmental sustainability, ethical labor practices, community engagement, and consumer education. Through the production of HDPE woven bags, eco packaging bags, and flexible food packaging bags, manufacturers have opportunities to reduce environmental impact, promote safety, and support a more sustainable supply chain. By embedding these principles into their operations, packaging companies contribute not only to business success but also to broader societal and environmental well-being. As the packaging industry continues to evolve, maintaining a strong focus on social responsibility will remain a critical factor in shaping its future.

English

English Español

Español عربى

عربى