Functionality and durability are very important for packaging bags. Among the wide variety of solutions available, PP woven bags have become a versatile choice for sectors ranging from agriculture and chemicals to food distribution and construction materials. Known for their unique balance of strength and lightness, these bags are designed to meet the needs of industries that require efficient bulk handling and storage.

Strength Without Excess Weight

The primary advantage of PP woven bags lies in their structure. Made from polypropylene strips woven together, the bags are inherently tough yet lightweight. This means they can withstand heavy loads while reducing the overall packaging weight. In industries such as cement, fertilizer, or grain storage, this combination translates into better handling, easier transport, and lower logistical costs without compromising reliability.

Applications Across Industries

PP woven bags are widely used for packaging commodities like rice, flour, animal feed, seeds, and powdered chemicals. Their ability to handle both dry and semi-moist materials makes them suitable for multiple applications. Unlike many single-use plastic bags, these woven products are strong enough to be reused, extending their service life in supply chains.

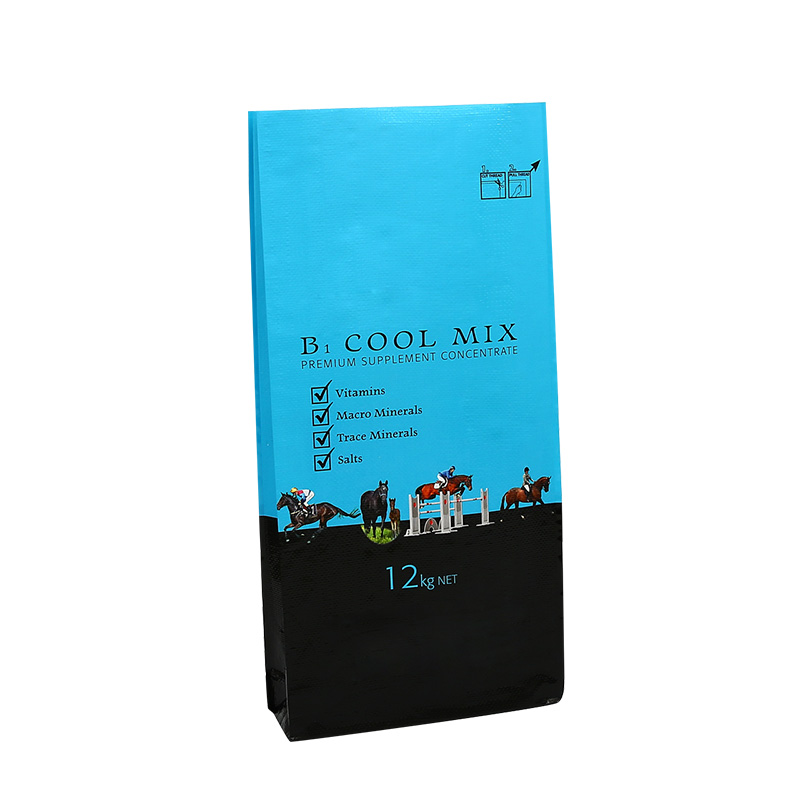

Another growing application is in PP woven printed bags, where advanced printing techniques allow companies to add branding, product details, and safety instructions directly onto the bag's surface. This not only improves consumer recognition but also supports regulatory compliance by ensuring clear labeling.

Flexible Packaging Products and Their Role

The packaging sector has increasingly embraced flexible packaging products due to their adaptability. PP woven bags fall within this category as they can be produced in different sizes, shapes, and with various finishing options, such as laminated surfaces for moisture protection. Flexibility in design enables industries to customize packaging solutions that meet their unique operational needs. For instance, in the agricultural sector, PP woven sacks can be tailored with ventilation features for products like onions or potatoes, ensuring freshness during transportation.

Comparison with Sealed Paper Bag Packaging

While PP woven bags are highly valued for their strength and reusability, sealed paper bag packaging continues to play an important role in certain industries. Paper bags are often chosen for products requiring a clean, dust-free environment or where a more natural look is desired. However, compared to paper bags, PP woven sacks generally offer greater resistance to tearing, puncturing, and moisture.

In some cases, hybrid solutions have emerged, where paper and woven polypropylene are combined to create multi-layer bags. This design integrates the durability of woven plastic with the aesthetic and protective qualities of paper. Such innovations highlight the evolving nature of industrial packaging and its ability to adapt to specific market needs.

Sustainability Considerations

As industries move toward environmentally conscious solutions, the sustainability of packaging materials becomes increasingly important. PP woven bags are recyclable, and many producers now use recycled polypropylene in their manufacturing processes. This reduces environmental impact while maintaining the functional qualities that industries require.

Compared with other packaging types, the durability of PP woven bags also contributes to sustainability by reducing the frequency of replacement. Longer service life translates to less waste, which is particularly important in large-scale operations handling bulk materials.

Advancements in Manufacturing

Manufacturing processes for PP woven bags have advanced considerably in recent years. Improvements in extrusion, weaving, and lamination technology allow for higher production efficiency and more consistent product quality. Automated systems ensure accurate sizing, sealing, and printing, which directly benefits industries that depend on precise packaging for storage and transportation.

These advancements also support innovation in bag features. Anti-slip coatings, UV resistance, and water-repellent laminations are just a few of the enhancements available today. Such features expand the range of applications for PP woven packaging, making them even more adaptable across different industries.

Global Market Outlook

The global market for PP woven sacks continues to expand as industries seek reliable, cost-effective, and adaptable packaging solutions. Growth in agricultural exports, construction projects, and chemical manufacturing drives demand for heavy-duty yet lightweight packaging. The shift toward sustainable materials further reinforces the value of PP woven products, particularly as companies aim to balance operational efficiency with environmental responsibility.

As technology and sustainability goals continue to shape the packaging sector, PP woven bags are positioned to remain a vital component of industrial and commercial supply chains. Their advantages in durability, flexibility, and recyclability ensure that they provide tangible value for businesses seeking reliable and efficient packaging.

English

English Español

Español عربى

عربى