The food industry relies heavily on efficient and reliable packaging solutions to ensure product safety, maintain quality, and optimize distribution. Among the key options available, woven sacks bags, paper bags for food packaging, and industrial paper bags have emerged as practical choices for a wide range of applications. These packaging types offer versatility, durability, and compatibility with different food products, making them increasingly relevant in modern industrial settings.

Woven Sacks Bags

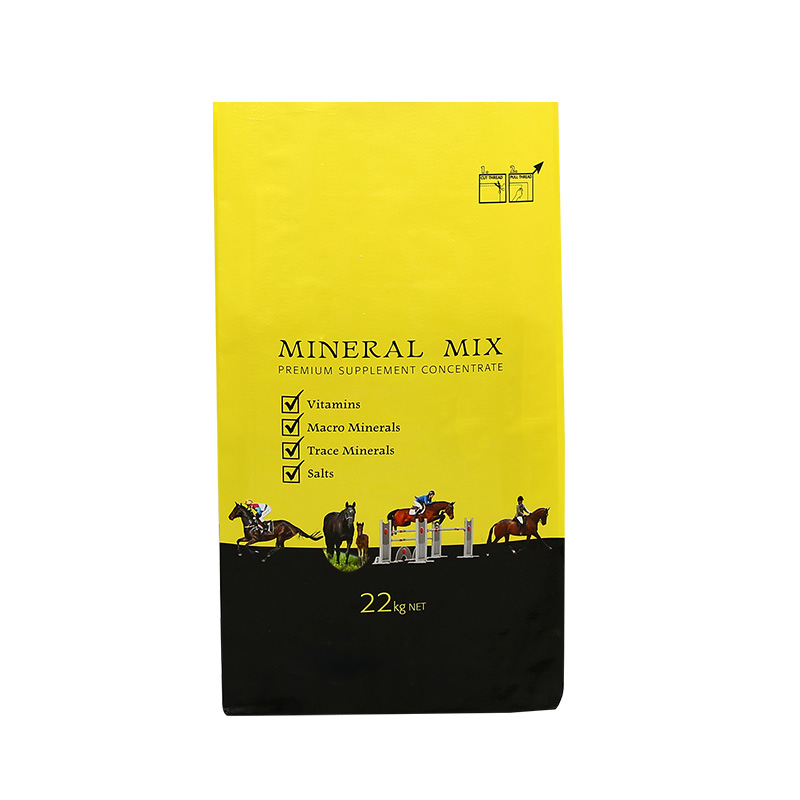

Woven sacks bags are designed to handle bulk food items such as grains, rice, sugar, and animal feed. The woven structure provides reliable strength and tear resistance, which is essential for both transportation and storage. These bags are typically made from polypropylene or similar materials that offer moisture resistance and longevity. In addition, woven sacks bags can be manufactured in different sizes and thicknesses to accommodate specific product weights and handling requirements. Their stackability allows for efficient warehouse management, while the material's flexibility reduces the risk of spillage or product damage. Many manufacturers also incorporate surface coatings or lamination to enhance barrier properties against humidity or dust, further protecting food quality during transit.

Paper Bags for Food Packaging

Paper bags for food packaging provide an alternative that aligns with growing environmental concerns and sustainability efforts. These bags are widely used for products like flour, sugar, snacks, and other dry foods. They are valued for their biodegradability and recyclability, offering a more environmentally responsible choice compared to traditional plastic packaging. Paper bags can be produced with multi-layer structures to improve strength and prevent tearing while maintaining flexibility. Food-grade adhesives and coatings are often applied to ensure the safety and hygiene of packaged items. Moreover, paper bags for food packaging can be printed with branding or product information, enhancing visibility and consumer engagement. Many food manufacturers are exploring innovative designs that allow easy opening, resealing, or portion control without compromising the integrity of the contents.

Industrial Paper Bags

Industrial paper bags extend the advantages of paper packaging to larger-scale applications and heavy-duty products. These bags are commonly used in processing plants, bakeries, and bulk distribution centers where food items are transported in significant quantities. Designed to support higher weights, industrial paper bags often feature reinforced bottoms, gussets, or multi-ply constructions to prevent failure during handling. Like paper bags for food packaging, industrial paper bags can be adapted with moisture barriers or laminated layers to protect against environmental factors that could compromise product quality. The use of industrial paper bags in the food sector also supports inventory management by providing clear labeling areas and consistent sizing for automated handling systems.

Trends and Outlook

The outlook for industrial packaging in food applications reflects several ongoing trends. Sustainability remains a primary focus, with manufacturers increasingly turning to recyclable or compostable materials to meet regulatory and consumer expectations. At the same time, packaging solutions must balance environmental benefits with performance, ensuring that items like grains, flour, and sugar are delivered safely and efficiently. Both woven sacks bags and paper bags for food packaging are evolving in design and material selection to meet these demands.

Automation and digital printing are also influencing the market. Manufacturers can produce industrial paper bags and woven sacks bags with precise specifications, ensuring consistency across batches and facilitating faster production. Printed bags can display batch numbers, expiry dates, and branding clearly, supporting traceability and marketing efforts simultaneously.

In addition, there is an increasing focus on reducing packaging weight without compromising durability. Lightweight woven sacks bags allow for more efficient shipping and lower transportation costs, while well-designed paper bags for food packaging and industrial paper bags reduce material use and waste. These improvements contribute to overall operational efficiency while addressing sustainability goals.

As the food industry continues to expand and evolve, the role of industrial packaging remains critical. Woven sacks bags, paper bags for food packaging, and industrial paper bags provide reliable, versatile, and environmentally conscious solutions for a wide range of food products. Manufacturers and distributors benefit from these packaging types through enhanced durability, protection, and operational efficiency, while consumers gain confidence in product quality and safety. The ongoing development of materials, design innovations, and sustainable options ensures that these packaging solutions will remain integral to food applications across global markets.

English

English Español

Español عربى

عربى