Among the many forms of packaging used across industries, valve bags are gaining wider attention for their efficiency, durability, and adaptability. The global demand growth in industrial valve bags reflects not only the needs of manufacturers and distributors but also the transformation of entire supply chains.

Expanding Applications Across Industries

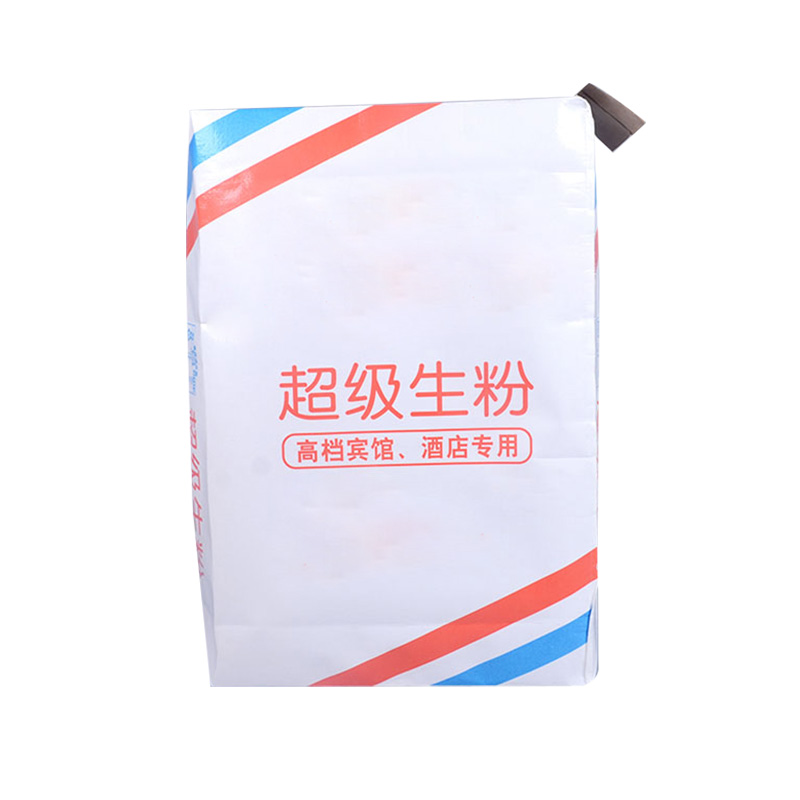

Industrial valve bags are widely used in packaging bulk materials such as cement, flour, chemicals, building products, and food ingredients. The valve design makes filling and sealing more convenient while also reducing spillage and ensuring consistent handling during transportation. As industries emphasize both efficiency and hygiene, sealed packaging bags play an essential role in reducing product contamination and maintaining integrity throughout the logistics process.

In construction, cement producers rely heavily on valve bags to deliver materials safely from plant to site. In agriculture and food processing, these bags are applied to grains, starch, flour, and animal feed, ensuring reliable packaging while supporting global distribution networks. For chemicals, valve bags allow controlled filling and reliable sealing, which is critical in maintaining safety standards during storage and shipment.

The Role of Woven Bag Packaging

One of the key developments driving growth in this market is the use of woven bag packaging. By combining strength and flexibility, woven materials extend the lifespan of the packaging and improve performance in demanding environments. Woven bag packaging is often chosen for products that need to withstand heavy stacking or rough handling during transport.

In addition, the design of woven packaging aligns well with valve bag structures, creating a hybrid solution that enhances efficiency in industrial use. For example, woven polypropylene bags can be fitted with valves for filling efficiency while retaining the durability of woven materials. This versatility makes them suitable for construction, agriculture, and chemical industries where bulk product packaging is a daily requirement.

Rising Importance of PE Woven Bag Solutions

Polyethylene-based woven bags, also known as PE woven bag products, are increasingly being adopted in packaging strategies. They are lightweight, durable, and resistant to moisture, making them suitable for various climate conditions and storage environments. The water-resistant qualities of PE woven bags make them especially valuable in agricultural and fertilizer packaging, where exposure to humidity or rain can significantly affect product quality.

In international logistics, PE woven bag solutions are often preferred due to their recyclability and lower overall cost of handling. They contribute to reducing packaging waste while ensuring secure protection for bulk goods. As manufacturers seek alternatives that balance strength and environmental responsibility, the application of PE woven bag products is set to expand further.

Sealed Packaging Bags and Quality Assurance

Another factor in the demand growth of industrial valve bags is the increasing use of sealed packaging bags. With stricter requirements for hygiene and safety in food and pharmaceutical industries, sealing technologies have become integral to modern packaging lines. Sealed packaging bags help prevent product leakage, contamination, and tampering, thus providing higher confidence for both producers and consumers.

The combination of valve bag filling efficiency with advanced sealing options allows packaging producers to meet the expectations of industries that require secure and long-term storage. For example, powdered milk, flour, and food additives are now often packed in valve bags with improved sealing systems to maintain freshness and compliance with food safety standards.

Market Drivers Behind Global Growth

Several factors are behind the growing demand for industrial valve bags worldwide. The steady expansion of the construction industry in developing markets has increased the consumption of cement and building materials, which rely heavily on valve bags. Second, the global rise in packaged food production is accelerating the adoption of sealed packaging bags and woven bag packaging. Third, international trade requires packaging that can endure long-distance transportation without compromising quality, creating higher demand for durable materials like PE woven bags.

Additionally, the shift toward environmentally responsible packaging encourages manufacturers to explore recyclable and reusable options. Woven materials and polyethylene structures fit well within this framework, giving valve bags a strong position in the future of industrial packaging.

Outlook for the Future

Looking ahead, the industrial valve bag market is expected to continue its upward trajectory as businesses seek practical, safe, and sustainable packaging solutions. Whether in construction, agriculture, food, or chemicals, valve bags supported by woven bag packaging and PE woven bag technologies will remain central to supply chain efficiency. The integration of sealed packaging bags will further reinforce quality assurance, meeting the demands of modern industries that value both durability and safety.

As companies expand globally, packaging solutions that offer flexibility, recyclability, and secure handling will be essential in maintaining reliable distribution channels. Industrial valve bags, with their adaptability to diverse sectors, are positioned to remain a critical part of packaging strategies worldwide.

English

English Español

Español عربى

عربى